We offer a wide range of on-site welding and fabrication solutions to meet your needs. This service is fully mobile.

We use dual voltage 110 – 240v equipment to comply with construction site health and safety regulations and standards. We carry different types of welding and cutting machines with us at all times, including a portable welder/generator in the event of not having electricity on site.

Arc Welding

Mig Welding

Tig Welding

Stainless Steel Welding

Oxy-Acetylene cutting

Drilling & Punching

Our professionally coded operators are available 24 hours a day, 365 days a year.

Mag drilling RSJ framework in a detached newly built five bedroom home on one of Radlett's most prestigious roads. www.relichomes.co.uk

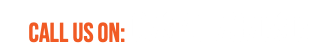

New Installation of mezzanine floor in new warehouse full of Link 51 racking

130 meters of estate style deer proof fencing installed beside a private house and public footpath.

Faithful reproduction of a corroded 75 year old art deco railing

2 - 3

Case Study One

Metal site gates designed to be easily assembled and disassembled to move from site to site.

They have a feature that when closed the gates cannot be lifted off the hinges, but can be when open. The hinges are inaccessible from the outside.

The advantage of these gates is that no section is greater than 8ft by 4ft so they are handy for storage and transportation.

www.relichomes.co.uk

Case Study Two

During the expansion project at Lister Hospitals Accident and Emergency Department a new canopy was erected.

An error in manufacture meant that the rain water was not draining away correctly.

DJBUK were called in to rectify the problem requiring us to work at height.

Case Study Three

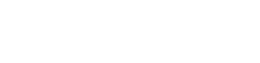

This Ballast box is one of the projects completed for scientific testing company Element. Although they have their own welders they were not confident of their abilities and contacted DJBUK.

Due to the stresses that will be put on this structure they wanted the works to be completed by a coded welder.